… about Sheet Metal Prototype, Inc.

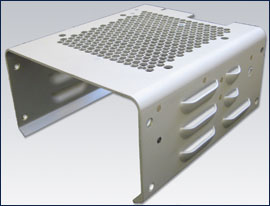

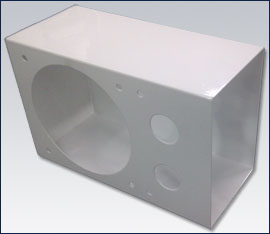

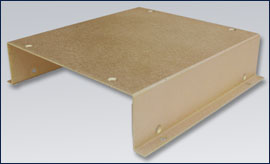

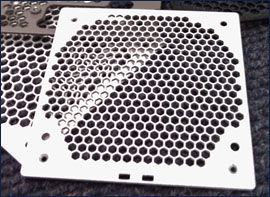

Sheet Metal Prototype, Inc. has been providing our customers with quality, close-tolerance parts for over 30 years. We specialize in lighter gauge materials, anywhere from .008 thick up to .250 in some alloys. We work in steel, aluminum, pre-coated alloys, copper, brass, and some plastics, and utilize three CNC turret presses to punch out any contour you might require. These are backed up by complete quality control, shearing, deburring, brake, welding and hardware departments. We only use top grade, prime materials, with traceability back to the original manufacturer, for every piece we create. We can provide certificates of conformance, material, and plating/paint certifications for any job that requires it. All certifications are scanned by job and kept on record indefinitely.

Experience and Diversity

Sheet Metal Prototype, Inc. caters to a wide and varied customer base across a variety of industries. Some of the industries we have served include:

- Audio and Video

- Electronics

- Lighting

- Power Supply

- Appliance/Food

- Aerospace/Military

- Printing

- Machinery

- Water Filtration

- Camera

- Hobby

- Gaming

- Parking

- Pet Industry

If you don’t see your particular industry here, chances are we’ve done something similar to your product for a previous customer. Let us add your industry to our ever-growing list.

Precision and Quality Control in Every Step

All of our quality control tools, such as calipers, height gauges, pins and granite blocks are kept up to date and precise with an outside supplier who certifies all tools at regular intervals. That includes company tools and employee tools.

The list below includes just a sampling of the precision machinery we use to produce your products every day.

- 3 CNC Strippit turret presses with auto-index capabilities

- Strippit 30/30 turret press

- Wysong shear

- 2 timesaver sanding machines

- Hand tools for grinding, deburring and finishing

- 3 brakes, each with a capacity of 6’ 60tons

- 2 welding machines

- Spot welders, and weld stud guns

- Mills and drill presses

- 2 Haeger presses for fixed hardware installation

- Inspection equipment, regularly inspected by an outside source

Oh, and we also have a truck that makes local deliveries right to your door.

Family Owned Since 1982

Conveniently located in the San Fernando Valley since 1982, Sheet Metal Prototype, Inc. has been at our current location in Northridge for almost 14 years. We have established ourselves as a customer-oriented supplier, conforming our schedule to accommodate our customer’s needs and requirements. Need a sheet metal housing for a show next week? Need a production run very quickly to supply a customer’s unexpected demand? Let’s get it done.

Don’t have time to find a supplier to do the plating, painting and silkscreen that your project requires? Place the order with us and we will take care of it all. We work with only the best subcontractors to ensure that the end product is exactly what you were looking for.

Bring in your idea, sketched out on a piece of cardboard or precisely drawn on CAD software, and we’ll take it from there.

The Service You Expect, The Quality You Demand

Our mission at Sheet Metal Prototype, Inc. is to meet or exceed your expectations. Our customer base has been built over the last 30 years with referrals and unsolicited word-of-mouth testimonials that have allowed us to grow and diversify. Give us a call, or send us a Request for a Quote, and see what we can do for you.